Servicios Personalizados

Articulo

Latin American applied research

versión On-line ISSN 1851-8796

Lat. Am. appl. res. vol.44 no.4 Bahía Blanca oct. 2014

Creating agile supply chains by tads

M. Balaji†, V. Vel Murugan‡ and N.R.Arun Kumar§

† Senior grade Assistant professor, Department of Mechanical Engineering, Kumaraguru College of Technology, Coimbatore 641049, India. Corresponding author: balpurush@rediffmail.com

‡ Principal, Sree Sakthi Engineering College, Coimbatore 641104, India. velgoudham_v@yahoo.com

§ PG Industrial engineering scholar, Kumaraguru College of Technology, Coimbatore 641049, India. nrarunkumarie@gmail.com

Abstract— Global markets are now becoming volatile in most industries and the importance of their abilities to adapt to rapid and unexpected changes have surfaced. Modern organizations have to respond quickly to their customers' dynamic demands without compromising on quality, productivity and cost. Achieving agility lies in de-signing agile friendly processes and thus firms need to concentrate on their supply chains and its enablers in the attempt of redressing themselves as responsive supply chains. To evaluate and improve the levels of supply chain agility, a model called Total Agile Design System (TADS) is proposed. TADS as a methodology identifies supply chain enablers and prioritize them in order to achieve supply chain agility. In this scoring model, agility index before and after implementation of TADS are measured and discussed. The results validate the proposed model and lend evidence to the current thinking of impinging on agile concepts in traditional supply chains for competitive advantage and survival.

Keywords— Responsive Supply Chains; TADS; Agility Index; Competitive Advantage.

I. INTRODUCTION

Modern organizations are facing enormous challenges and competition in the market due to rapid changes in customers taste and diversity. Today's organizations are forced to look beyond lean manufacturing practices and six sigma techniques and are in the adverse need of re-constructing the process of the relationships between supply and demand through TADS. Apart from trimming inventory expenses through lean principles and achieving zero defects through six sigma concepts, historical manufacturers are compelled to respond quickly to customer requirements and provide opportunities for global competitiveness in the cost driven manufacturing sector. Supply chain agility represents the rapid reaction potential of a supply chain on market changes and customer demands. Agility is the successful blend of speed, flexibility, innovation, proactiveness, quality and profitability through the integration of resources and best practices in an organization to provide customer-driven products and services in a fast changing market environment. In the present trend, determination of supply chain agility would indicate a firm's organizational superiority.

Vinodh et al. (2010) were the first to propose and implement a concept called TADS as a measure of the agility index in a traditional manufacturing system. Their work revealed the fact that modern manufacturing organizations should be capable of reconfiguring them-selves to suit the dynamic customer demands. According to Balaji et al. (2011), when innovation in the product line becomes infeasible or not cost effective, the firms should concentrate on their supply chain and its enablers and try to make existing chains flexible. They have triggered the possibility of applying the concept of TADS in supply chains to increase returns on investment and create delighted customers. Agarwal et al. (2006) analyzed the fact that flexibility is needed in any supply chain to encounter the uncertainty in manufacturing by developing a conceptual framework encapsulating market sensitiveness, process integration, information drivers and flexibility measures for supply chain performance. Gunasekaran et al. (2008) had expressed his views on Agile Manufacturing (AM) and Supply Chain Management (SCM) complementing each other for improving organizational competitiveness. An attempt to integrate AM and SCM in creating a responsive supply chain has been done which can be employed as a competitive strategy in a networked economy of virtual organizations. Bottani (2009) has built a house of quality on a new product and applied fuzzy logics to translate linguistic judgments with a view point to integrate agile attribute and agile enablers for achieving competitive characteristics. According to Gunasekaran (1998), markets are becoming highly diversified and facing unexpected changes becomes the key factor for success. His research has identified seven key enablers for the development of an agile manufacturing system. Yusuf et al. (2004) had focused on supply chain integration and explored the relationship between emerging patterns and attainment of competitive objectives by developing a multiple regression model which involved 600 companies in the UK. According to Tseng and Lin (2011), a Fuzzy agility index for an enterprise is composed of agility capability ratings and a total relation weight with agility drivers which could be developed to measure the agility level of an enterprise. Vinoth et al. (2013) confines that any assessment model of an agile supply chain will fail unless the agile manufacturing paradigm of the organization continuously supports the supply chain. Their work has contributed towards building an agile supply chain assessment model for computing fuzzy agile supply index using a fuzzy logic approach.

The review of the above papers certainly exposes the importance of agility in any manufacturing firm and its supply chain. In particular, Vinodh et al. (2010) has successfully used TADS to measure agility index in an organizational setup, but did not go beyond the organizational boundary. Balaji et al. (2011) had proposed the chances of using TADS model for assessing the agility index of a supply chain but did not implement TADS and improve the agility index of a supply chain. This narrow gap opened the possibility of an innovative research and triggered our efforts in assessing and improving the agility index of an organization's supply chain using TADS. With this backdrop, our paper pro-poses a model called TADS which as a tool quantifies the agility based on the various agility criteria framed within an organization's boundaries. A parameter named agility index has been coined to tabulate the agility level of supply chains before and after implementation of TADS. TADS is incorporated with questionnaires to measure agility index and address drag factors from the confined list of 14 agility criteria. The corresponding drag factors of the agility criteria have been identified and eliminated to the maximum possibility of turning the industry's supply chain into an agile entity.

The manuscript structure is as follows. Section II.A reports the exploration of literature for finalizing agile supply chain criteria were as Section II.B elaborates on the TADS methodology. A few words about the organization and industry structure is discussed at section II.C and the procedure for measurement of agility index is explained at section II.D. Section II.E elucidates the assessment of agility index before TADS implementation and section II.F identifies the possible drag factors and its corresponding remedial measures. Section II.G describes about the assessment of agility index after TADS implementation and section II.H presents the discussions followed by the conclusions of the research in Section III.

II. METHODS

A. Agile Supply Chain Criteria

Agile Supply Chain (ASC) criteria are wagons of agility which have the potential to drive supply chains towards agility. Based on the rich literature and research findings of the past, this research paper identifies 14 criteria listed below. Nevertheless, the proposed criteria will prove to be vital in assessing and improving agility levels of the supply chain on screen.

- Culture of Change (Sherehiy et al., 2007)

- Organizational Structure(Mashayekhi et al., 2011)

- Customer Relationship Management (Zhang, 2011)

- Production Planning (Hasan et al., 2012)

- Process Integration (Lin et al., 2006)

- Materials Management (Dove, 1996)

- Distribution Management/Networks (Vinodh et al., 2013)

- Employee Involvement (Vinodh et al., 2010)

- Information Integration (Tseng and Lin, 2011)

- Supplier Relationship Management (AL-Tahat and Khaled, 2012)

- Marketing Sensitiveness (Tseng and Lin, 2011)

- Customer order fulfillment process (Lambert and Cooper, 2000)

- Customer Reaction and Proactive Anticipations (Vinodh et al., 2008)

- Customer Service Management (Lambert and Cooper, 2000)

B. Total Agile Design System (Tads) Methodology

The results of the literature survey on Supply Chain Agility reveal that there have been limited attempts for evaluating agility levels of supply chains. TADS have been considered (Vinodh et al., 2010) for agile customization when the production process needs to be customized according to the dynamic requirements of the customers. TADS quantifies the supply chain agility of the organization by adopting new technological advancements. This agility quantification tool uses a questionnaire based approach method and facilitates the apportionment of scores among the defined list of ASC criteria (Anantatmula and Kanungo, 2006; Chieh-Wen et al., 2008; Dorabjee et al., 1998).

An agility index can be used to assess the agility levels of a supply chain on a 2000 score scale. A TADS team of 10 members were identified and instructed about the features of agile quantification tool and ASC criteria. Later the questionnaires pertaining to all criteria were given to them and with their responses, the agility index was computed based on agility scores using the formula for agility index (Vinodh et al., 2010).

| Agility index = Total score/2000 | (1) |

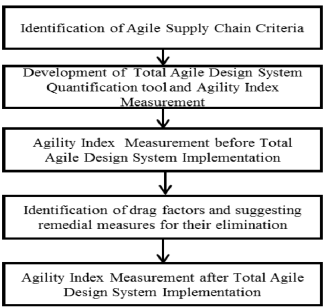

The agility index score before TADS implementation opens the possibilities of identifying drag factors and suggesting remedial measures for their elimination in order to strengthen the weakest ASC, as depicted in Fig. 1. Successful removal of drag factors using suit-able remedial measures during TADS implementation phase can be eventually seen with a positive change in the agility index score after TADS implementation.

Fig. 1. TADS Methodology

C. About the Organization and Industry Structure.

The firm located in Tamil Nadu, India is a specialist in the design, development and production of auto-mated material handling equipments. In addition, the company provides a comprehensive service ranging from consultancy to total project management and a 24 hour service logistic support. However, the firm is challenged in trading off between demand and supply with its traditional supply chain and thus fearing the losses of customer goodwill in longer run.

D. Measurement of Agility Index

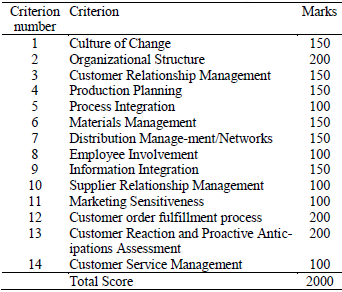

In order to measure agility index, an agility quantification tool developed in previous research was adopted (Vinodh et al., 2010). The agility quantification tool has its root on the 14 criterion that determines the agility level of an organization and is distributed across a total score of 2000 as shown in Table 1.

Table 1. Distribution of Scores for Agile Criteria

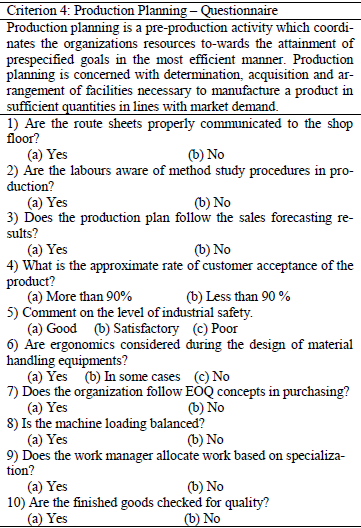

This questionnaire enables the responders to indicate the agility level from the point of view of agile criterion. One such sample questionnaire pertaining to the criterion Production Planning is shown in Table 2.

Table 2. Questionnaire Pertaining To Production Planning Criterion

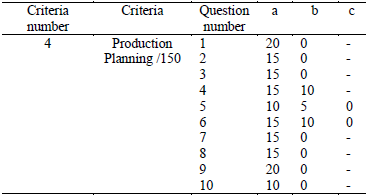

After the responder completes the questionnaire, a score allotment table (Table 3) has to be referred in order to convert the responses into scores and for computing the agility index. The guidelines for assigning maximum scores to the answers of the questionnaires was strictly based on the recommendations of the TADS team members identified by the organization.

Table 3. Score Allotment Table Pertaining to Production Planning Criterion

E. Assessment of Agility Index Before TADS implementation

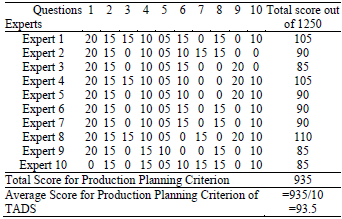

The implementation study began by measuring agility index before TADS implementation in the organization. The responses of TADS team members were recorded and the scores were tabulated. The score pertaining to ASC criterion production planning is shown in Table 4. Likewise, the mean scores were calculated by referring to the responses of the TADS team members against the corresponding ASC criterion as shown in Table 5. The total score was estimated as 1246.5 out of 2000 and thus the agility index before TADS implementation was 0.6233.

Table 4. Score for Production Planning Criterion Before Implementation of TADS

Table 5. Total Score Summary

The TADS implementation study carried out in the firm integrates functional sections of the firm such as design, materials supply, production, distribution and sales. The objective was to provide the right number of products and services to the right places at the right time in order to meet the desired level of customer requirements and enable overall supply chain profitability.TADS methodology aims at achieving agility through strategic partnerships, integrating resources, forming seamless business environments, continuous innovations, privileged customer responses, leveraging human skills and integration of information technology. After overcoming a series of hurdles, the firm's supply chain progressed on agile forefronts. The drag factors hindering the formation of ASC were eliminated one by one which paved the way for creating an adaptive and responsive supply chain.

F. Drag Factors and Remedial Measures

Various drag factors that obstruct the achievement of an ASC were identified and addressed. Two of the notable drag factors and remedial measures for Production Planning criteria are shown below.

Imbalanced inventory management systems:

Imbalanced inventory management systems are those which either holds huge surpluses leading to unproductive capital tie-up or large-scale non-availabilities leading to unsatisfied customers.

Remedial measures:

- Better inventory management through selective inventory control practices, standardization of products, timely identification and disposal of surpluses.

- Following Just In Time (JIT) principles in working out realistic requirements and enabling the order of right quantities at the right time with right delivery schedules.

- Aggregate Planning well in advance for synchronizing production flow.

- Using Master production scheduling procedures to summarize the requirements of various departments like sales, finance and manufacturing in order to schedule production and the purchasing of materials within the capacity and re-sources available to the production system.

Improper Production Control which leads to inefficient production systems:

Improper production control is characterized by inadequate planning and lack of coordination in manufacturing activities which lacks prompt delivery, quality, cost effectiveness and efficient resources utilization.

Remedial measures:

- Effective line balancing by leveling the workload across all processes in a manufacturing cell to remove bottlenecks and excess capacity.

- Using visuals to signal the need to start or pause production and adopting a pull kanban system to keep manufacturing products based on actual demand rather than forecasted demand.

- Expediting the process flow and ensuring that the work is carried out as per the plan and delivery schedules are met by following techniques like status reporting, attending bottlenecks, controlling deviations from planned performance levels, following up and monitoring the progress of work through all stages of production and modifying the production plans if necessary.

TADS measurements certainly demands implementation of some external mechanisms like JIT, Materials Requirement Planning, Aggregate Planning etc., from the view point of production planning criterion. This may be further extended with similar mechanisms for the remaining 13 criteria to remove the undesired effects on the creation of an ASC. An important consideration is that, when an organization implements all these re-medial measures, its supply chain can become an ASC with significant improvements in agility levels.

G. Agility Index After TADS Implementation

For assessing the agility index after implementation of TADS, the team members were requested to anticipate and respond to the performance of the system. The same questionnaires which were earlier used were given to the TADS team members and their responses were used to calculate the scores against each ASC criterion after implementation. As expected, the total score escalated to 1700.5 out of 2000 and thus the agility index after TADS implementation was 0.8503. The percentage improvement in agility as a result of TADS implementation against all ASC criteria was computed and the results are exhibited in Table 5.

H. Discussion

TADS certainly have the tendency to tap the potential opportunities in a turbulent supply chain environment. By implementing TADS, it is evident that the agility index can be improved by a grand margin of 22.70% for the organization under focus. It also opens the window of micro studying the drag factors in agility implementations which have never surfaced in most researches in recent past. In addition, this research has contributed towards a better understanding of eliminating drag factors by using appropriate remedial measures for improving the agility index of supply chains. The findings are of direct relevance to harness supply chain agility levels in responding to market changes. Importantly, the results indicate that enhanced supply chain agility has positive impacts on the firm's sales, market share, profitability, speed to market and customer satisfaction.

III. CONCLUSIONS

It is ardent that supply chain agility can be achieved by means of improved coordination among the different levels of supply chain which is the greatest potential asset of any supply chain. By improving the coordination among the phases, negative impacts of lack of coordination can be minimized to a greater extent. It makes the supply chain more profitable and flexible. The advantage of TADS is to create the most value, not simply for the organizations, but for the entire supply chain network including the end customer. At the onset, what is needed in this volatile market is the redesigning of the supply chains to achieve lean status and flexibility with the help of agility quantification tools.

REFERENCES

1. Agarwal, A., R. Shankar and M.K. Tiwari, "Modeling the metrics of lean, agile and leagile supply chain: An ANP-based approach," European J. of Opera-tional Research, 173, 211-225 (2006).

2. AL-Tahat, M.D. and K.M. Bataineh, "Statistical Analyses and Modeling of the Implementation of Agile Manufacturing Tactics in Industrial Firms," Mathematical Problems in Eng., 2012, 1-23 (2012).

3. Anantatmula, V. and S. Kanungo, "Structuring the un-derlying relations among the knowledge manage-ment outcomes," J. Knowl. Manag., 10, 25-42 (2006).

4. Balaji, M., G. Karuppusami, R. Sudhakaran and A. Chobiya Ashwini, "TADS Approach in Supply Chain Agility," Int. J. of Scientific & Eng. Research, 2, 1-5 (2011).

5. Bottani, E., "A fuzzy QFD approach to achieve agility," Int. J. Production Economics, 119, 380-391 (2009).

6. Chieh-Wen, S., M-J. Shen and M-C. Chen, "Special in-terest tour preferences and voluntary simplicity life-style," Int. J. of Culture, Tourism and Hospitality Research, 2, 389-409 (2008).

7. Dorabjee, S., C.E. Lumlee and S. Cartwright, "Culture, Innovation and successful development of new medicines - an exploratory study of the pharmaceutical industry," Leadership. Organ. Dev. J., 19, 199-210 (1998).

8. Gunasekaran, A., "Agile manufacturing: enablers and an implementation framework," Int. J. Prod. Res., 36, 1223-1247 (1998).

9. Gunasekaran, A., K.H. Lai and T.C. Edwin Cheng, "Responsive supply chain: A competitive strategy in a networked economy," The Int. J. of Manag. Science, 36, 549-564 (2008).

10. Hasan, M.A., J. Sarkis and R. Shankar, "Agility and production flow layouts: An analytical decision analysis," Comp. & Ind. Eng., 62, 898-907 (2012).

11. Lambert, D.M. and M.C. Cooper, "Issues in Supply Chain Management," Ind. Marketing Manag., 29, 65-83 (2000).

12. Lin, C.T., H. Chiu and P-Y. Chu, "Agility index in the supply chain," Int. J. of Production Economics, 100, 285-299 (2006).

13. Mashayekhi, A.N., A.T. Eshlaghy, A. Rajab-Zadeh and M. Majid Razavian, "Determination constructs validity of an agile organization model by using factor analysis," J. of Ind. Engineering International, 7, 75-89 (2011).

14. Dove, R., "Tools for Analyzing and Constructing Agility," Agility Forum, PA96, 1-13 (1996).

15. Sherehiy, B., W. Karwowski and J.K. Layer, "A review of enterprise agility: Concepts, frame-works, and attributes," Int. J. of Ind. Ergonomics, 37, 445-460 (2007).

16. Tseng, Y.H. and C-T. Lin, "Enhancing enterprise agility by deploying agile drivers, capabilities and providers," Information Sciences, 181, 3693-3708 (2011).

17. Vinodh, S., S.R. Devadasan, K.E.K. Vimal and D. Kumar, "Design of agile supply chain assessment model and its case study in an Indian automotive components manufacturing organization," J. of Manufacturing System, 32, 620-631 (2013).

18. Vinodh, S., G. Sundararaj and S.R. Devadasan, "Meas-uring organisational agility before and after imple-mentation of TADS," Int. J. Adv. Manufacturing Technology, 47, 809-818 (2010).

19. Vinodh, S., G. Sundararaj, S.R. Devadasan, D. Kuttal-ingam, P.L. Meenakshi Sundaram and D. Rajana-gam, "Enhancing competitiveness through CAD phase of Total Agile Design System," Int. J. Process Manag. and Benchmarking, 2,197-220 (2008).

20. Yusuf, Y.Y., A. Gunasekaran, E.O. Adeleye and K. Sivayoganathan, "Agile supply chain capabilities: Determinants of competitive objectives," European J. of Operational Research, 159, 379-392 (2004).

21. Zhang, D.Z., "Towards theory building in agile manu-facturing strategies- Case studies of an agility taxon-omy," Int. J. of Production Economics, 131, 303-312 (2011).

Received: February 5, 2014

Accepted: April 23, 2014

Recommended by Subject Editor: Mariano Martín