Servicios Personalizados

Articulo

Latin American applied research

versión On-line ISSN 1851-8796

Lat. Am. appl. res. vol.44 no.4 Bahía Blanca oct. 2014

On correction to temperature field due to variable thermal conductivity in case of boundary layer flow past a moving cylinder with suction

R.R. Rangi and N. Ahmad

Department of Mathematics, Jamia Millia Islamia, New Delhi-110025, India. E-mail: rdrekhadahiya@gmail.com.

Abstract— The boundary layer flow of viscous incompressible fluid over a moving cylinder with suction has been considered to study heat transfer with variable thermal conductivity. The heat transfer is affected by thermal conductivity for the liquid metals within 0°F to 400°Frange. In this case, we observe that the transfer of heat behaves differently in two different regions: 0≤η≤1and η>1. Hence, we solve the two boundary value problems to draw out recommendations. The results have been discussed graphically.

Keywords— Boundary Layer Equation; Energy Equation; Variable Thermal Conductivity; Prandtl Number.

I. INTRODUCTION

The boundary layer flow with heat transfer due to stretching flat plate or cylinder not only of practical interest in fibre technology, metal extrusion process etc. but also of theoretical interest. The production of polymer sheets and plastic films is based on this technology. There are number of examples which include the cooling of an infinite metallic plate in a cooling bath such as the boundary layer along material handling conveyers, the aerodynamic extrusion of plastic sheets, the boundary layer along a liquid film in condensation processes, paper production, glass blowing, metal spinning and drawing plastic films. The quality of the final product depends on the rate of heat transfer at the stretching surface. Sakiadis (1961) was the first to consider the boundary layer flow on a moving continuous solid surface, whose work was subsequently extended by Rotte and Beek (1969), Bourne and Elliston (1970). Crane (1970) extended this concept to a stretching sheet with linearly varying surface speed and presented an exact solution for steady two-dimensional flow over stretching surface in a quiescent fluid. Since then, many authors have considered various aspects of this problem and obtained similarity solutions. A similarity solution is one in which the number of independent variables is reduced by at least one, usually by a coordinate transformation. The idea is analogous to dimensional analysis, but instead of parameters, like the Reynolds number, the coordinates themselves are collapsed into dimensionless groups that scale the velocities (White, 2006).

On the other hand, Pop et al. (1990) have studied the problem of boundary layer flow past a moving longitudinal cylinder in a non-Newtonian power-law fluid at rest. The boundary layer flow due to a stretching vertical surface in a quiescent viscous incompressible fluid when the buoyancy forces are taken into consideration have been considered in the papers by Daskalakis (1993), Chen (1998, 2000), Lin and Chen (1998), Ali (2004), Partha et al. (2005) and Ishak et al. (2007, 2008). Lin and Shih (1980, 1981) considered the laminar boundary layer and heat transfer along horizontally and vertically moving cylinders with constant velocity and found that the similarity solutions could not be obtained due to the curvature effect of the cylinder. Pop et al. (1995) dealt the possibility of mass transfer through the cylinder wall. If the wall of the cylinder is porous or perforated, fluid at a prescribed temperature can be blown into the boundary layer (injection) or fluid at the wall surface can be withdrawn (suction).These mass transfer processes may measurably alter the flow and heat transfer characteristics.

Recently, Rangi and Ahmad (2012) investigated boundary layer flow past a stretching cylinder and heat transfer where they have use Keller-box technique to study flow and temperature fields. In this paper, following Pop et al. (1995), we consider heat transfer with variable thermal conductivity in case of moving cylinder with suction to study the heat transfer. We come across the correction to mean temperature field in two different regions.

II. MATHEMATICAL FORMULATION OF THE PROBLEM

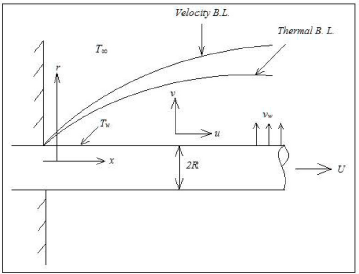

Consider a steady, axisymmetric boundary layer flow of a viscous incompressible fluid along a cylinder of radius R, which moves with the constant velocity. It is assumed that the surface of the cylinder is at a uniform temperature Tw, which is greater than the ambient temperature T∞. All over the cylinders surface, fluid is sucked in with a constant radial velocity vw. We use the coordinates x and r, where the x-axis is taken along the cylinder axis and the r-axis is in the radial direction as shown in Fig 1.

Figure 1. Physical model and coordinate system

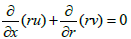

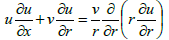

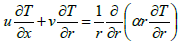

Under the assumption of boundary layer theory, the equations which model the problem under consideration are

| (1) |

| (2) |

| (3) |

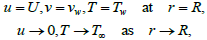

with the boundary conditions

| (4) |

where u and v are the radial and axial velocity components respectively, T is the fluid temperature, v is kinematic viscosity while density and specific heat are taken constant, α is thermal diffusivity and vw (<0) is the velocity of suction.

We define the following dimensionless boundary layer variables:

The axial coordinate

| (5a) |

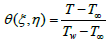

the similarity variable  and the temperature distribution

and the temperature distribution

| (5b) |

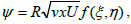

The stream function

| (6a) |

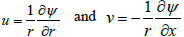

such that

| (6b) |

The continuity Eq. (1) is satisfied by Eq. (5) and Eq.(6). Thus Eq. (2) is transformed to

| (7a) |

with boundary conditions

At η=0

|

and as

| (7b) |

where  is the fluid suction (σ<0).

is the fluid suction (σ<0).

It has been observed that for liquid metals the thermal conductivity a varies with temperature in an approximately linear manner in the range from 0°F to 400°F. Therefore, we assume α as α=αa∞(1+ εθ).

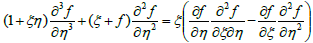

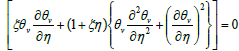

Now, the Eq. (3) reduces to

| (8a) |

with boundary conditions

| at η=0 θ=1 | |

and as  θ=0 θ=0 | (8b) |

From the Eq. (8a), we note that the heat transfer takes place in two parts, that is, one part of heat transfer is due to temperature difference and the other part is due to variable thermal conductivity. In Eq. (8a), if ε=0, we get the temperature field θ for the problem where thermal conductivity does not contribute, i.e. thermal conductivity is constant. Our aim is to analyze the temperature field which occurs due to variation in thermal conductivity. Thus the temperature field governed by the following boundary value problem

| (9a) |

| η=0 θm=1 | |

as as  | (9b) |

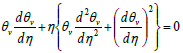

The temperature field which occurs due to variation of thermal conductivity is governed by

| (10a) |

| η=0 θv=0 | |

as as  | (10b) |

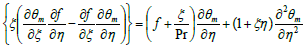

The solution of the problem posed by the Eq. (9a) and Eq.(9b) was discussed by Pop et al. (1995). Our aim is to analysis the contribution made by thermal conductivity. So, we write

| (11) |

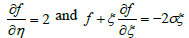

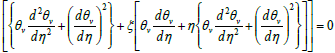

Applying the regular perturbation method as applied by Ahmad et at. (2010), we equate the terms independent of ξ and the dependent of ξ to zero and we get

| (12a) |

| (12b) |

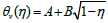

The Eq. (12a) is non-linear differential equation. Assuming its solution as

|

we have

|

The roots of this equation are 0 and ½, therefore

| (13) |

The general solution of Eq. (12a) is real only when 0≤η≤1. Therefore, the heat transfer due to variable thermal conductivity which is free from axial co-ordinate takes place within the dynamic region 0≤η≤. Thus, the boundary conditions (10b) may be replaced by

| η=0 θv=1 | |

, ,  | (14) |

Hence, the solution of the problem given by the Eq. (13) and Eq. (14) is

|

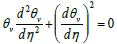

Looking at the Eq. (12b), we find that

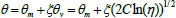

| (15) |

whose solution comes out to be

| (16) |

where C is the arbitrary constant. Here, we observe that qv is real only for η>1. Therefore this part of heat transfer occurs only in  . Also, we observe that this part of heat transfer depends on axial co-ordinate ξ. Finally, we have

. Also, we observe that this part of heat transfer depends on axial co-ordinate ξ. Finally, we have

for η>1. for η>1. | (16) |

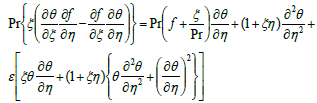

III. DISCUSSION AND RESULTS

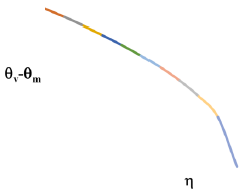

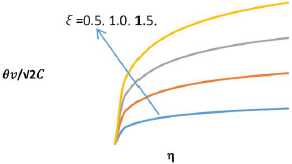

Analyzing the heat transfer with variable thermal conductivity in case of moving cylinder with suction, we come across that the contribution of variable thermal conductivity to heat transfer occurs in two regions: one in 0≤η≤1 and other in 1<η<∞. These two regions may be the outcome of suction. As the fluid from the immediate neighborhood of outer surface of cylinder has been sucked, the fluid from the outside region 1<η<∞ rushes to the region 0≤η≤1. Therefore, a new dynamical region comes into picture in which the heat transfer pattern is different from the heat transfer in 0≤η≤1. We summarize the results as below:

(i) Within the dynamic region 0≤η≤1, the temperature field is  which is independent of axial co-ordinate ξ. θm is referred as mean temperature and studied by Pop et al. (1995).

which is independent of axial co-ordinate ξ. θm is referred as mean temperature and studied by Pop et al. (1995).

(ii) Within the region 1<η<∞, the temperature field be- comes  which varies with axial co-ordinate ξ linearly.

which varies with axial co-ordinate ξ linearly.

(iii) If we put ε=0, the results are agreed with Pop et al. (1995).

Figure 2. Correction in mean temperature within 0<η<1

Figure 3. Correction in mean temperature θm within 1<η<∞ for ξ=0.5, 1.0, 1.5, 2.0

REFERENCES

1. Ahmad, N., Z.U. Siddiqui and M.K. Mishra "Boundary layer flow and heat transfer past a stretching plate with variable thermal conductivity," Int. J. Non-Linear Mechanics, 45, 306-309 (2010).

2. Ali, M.E., "The buoyancy effect on the boundary layers induced by continuous surfaces stretched with rapidly decreasing velocities," Heat Mass Transfer, 40, 285- 291 (2004).

3. Bourne, D.E. and D.G. Elliston, "Heat transfer through the axially symmetric boundary layer on a moving fibre," Int. J. Heat Transfer, 13, 583-593 (1970).

4. Chen, C.H., "Laminar mixed convection adjacent to vertical, continuously stretching sheets," Heat Mass Transfer, 33, 471-476 (1998).

5. Chen, C.H., "Mixed convection cooling of a heated, continuously stretching surface," Heat Mass Tranfer, 36, 79-86 (2000).

6. Crane, L.J., "Flow past a stretching plate," Z angew. Math. Phys., 21, 645-647 (1970).

7. Daskalakis, J.E., "Free convection effects in the boun dary layer along a vertically stretching flat surface," Can. J. Phy., 70, 1253-1260 (1993).

8. Ishak, A., R. Nazar and I. Pop, "Hydromagnetic flow and heat transfer adjacent to a stretching vertical sheet," Heat Mass Transfer, 44, 921-927 (2008a).

9. Ishak, A., R. Nazar and I. Pop, "Mixed convection on a stagnation point flow toward a vertical, continuously stretching sheet," ASME J. Heat Transfer, 129, 1087 - 1090 (2007).

10. Lin, C.R. and C.K. Chen, "Exact solution of heat transfer from a stretching surface with variable heat flux," Heat Mass Transfer, 33, 477-480 (1998).

11. Lin, H.T. and Y.P. Shih, "Buoyancy effects on the laminar boundary layer heat transfer along vertically mov ing cylinders," J. Chin. Inst. Eng., 4, 47-51 (1981).

12. Lin, H.T. and Y.P. Shih, "Laminar boundary layer heat transfer along static and moving Cylinder," J. Chin. Inst. Eng., 3, 73-79 (1980).

13. Partha, M.K., P.V.S.N. Murthy and G.P. Rajasekhar, "Effect of viscous dissipation on the mixed convec tion heat transfer from an exponentially stretching surface," Heat Mass Transfer, 41, 360-366 (2005).

14. Pop, I., M. Kumari and G. Nath, "Non-Newtonian boun dary-layers on a moving cylinder," Int. J. Engng. Sci., 28, 303-312 (1990).

15. Pop, I., T. Watanabe and H. Taniguchi, "Laminar boundary layer flow and heat transfer along a moving cylinder with suction or injection," Technische Mechanik , 2, 99-106 (1995).

16. Rangi, R.R. and N. Ahmad, "Boundary layer flow past a stretching cylinder and heat transfer with variable thermal conductivity," J. Applied Math., 3, 205-209 (2012).

17. Rotte, J.W. and W.J. Beek , "Some models for the calculation of heat transfer coefficients to a moving continuous cylinder," Chem. Engn. Sci., 24, 705-716 (1969).

18. Sakiadis, B.C., "Boundary-layer behaviour on continuous solid surfaces: I. Boundary-layer equations for two-dimensional and axisymmetric flow," AIChE J.,7, 26-28 (1961).

19. White F.M., Viscous Fluid Flow, McGraw-Hill, New York, (2006).

Received: January 9, 2013

Accepted: March 25, 2014

Recommended by Subject Editor: Walter Ambrosini