Servicios Personalizados

Articulo

Latin American applied research

versión On-line ISSN 1851-8796

Lat. Am. appl. res. vol.45 no.2 Bahía Blanca abr. 2015

Effect of pretreatments on sesame cake protein hydrolysis by alcalase

E. Demirhan, D. Killiç Apar and B.özbek

Yıldız Technical University, Department of Chemical Engineering, Davutpaşa Campus, 34210, Esenler/Istanbul, Turkey. E-mail: bozbek@yildiz.edu.tr

Abstract— In the present work, the effects of pretreatments on hydrolysis of sesame cake protein and enzyme stability were investigated. Heat, microwave and sonic pretreatments were applied to sesame cake protein as pretreatments before the enzymatic hydrolysis reaction. The sesame cake protein was hydrolyzed by Alcalase enzyme.

Keywords— Sesame Cake Protein; Alcalase; Heat Pretreatment; Microwave Pretreatment; Sonic Pretreatment.

I. INTRODUCTION

Plant proteins are increasingly being used as an alternative to proteins from animal sources to perform functional roles in food formulation. Knowledge of the kinetics of the hydrolysis reaction is essential for the optimization of enzymatic protein hydrolysis and for increasing the utilization of plant proteins in food products (Kim et al., 2004; Chabanon et al., 2007).

Pretreatments could be applied to the substrate for improving the efficiencies of the hydrolysis reactions. The rationale behind such pretreatments has been to improve the accessibility of the enzyme to the target bond in the substrate. Heat treatment is a physical technique frequently used in food industry to change the conformation of protein and to facilitate the enzymatic hydrolysis of proteins (Cui et al., 2009; Nordqvist et al., 2012). Microwave irradiation has recently been applied to accelerate chemical or enzymatic reactions due to the microwave-induced rapid heating and conformational or structural changes of the proteins along the peptide bonds (Zhong et al., 2005; Ye and Li, 2012). Ultrasound has been used to accelerate the rates of enzymatic reactions by using ultrasound as an enzymatic pretreatment to reduce particle size. In such cases, the reduction in particle size and consequent increase in the catalytic surface area are thought to reduce mass transfer limitations.

Therefore, the goal of the present study was to investigate the effect of pretreatments such as heat treatment, microwave irradiation and sonication on hydrolysis and solubilization of sesame cake as well as to test for enzyme stability.

II. METHODS

A. Materials

Sesame cake protein used in this research which contains 37.7% protein was obtained from Necdet Bükey A.Ş, Izmir. The enzyme used in this work was Alcalase 2.4L, a bacterial protease produced by Bacillus Licheniformis, obtained from Novozymes.

B. Pretreatments

For heat pretreatment, the sesame protein solution that contains 15 g protein per liter was heated up to 90°C and 100°C; and kept 30 minutes at these temperatures.

Microwave pretreatment was performed in a domestic digital microwave oven (Arcelik MD 594, Turkey). For this treatment, the sesame protein solution was heated by 540 and 720 W microwave irradiation for 10 minutes.

The ultrasonic pretreatments were performed by using Bandelin Sonopuls HD 2200 sonicator The tip of the horn was immersed about 2 cm into the 50 ml sesame cake solution and sonication was performed at constant duty cycle rate of 50 % for 80 and 120 W acoustic power rates for 30 minutes. During the sonication process the temperature of the solution was kept constant at 40°C.

C. Hydrolysis reaction

Hydrolysis experiments were carried out in a 400 ml jacketed reactor with magnetic stirring with pH and temperature control. After the pretreatments, all hydrolysis reactions were carried out 120 minutes in 0.2 liter of aqueous solutions, contains 15 g protein/L sesame cake protein, at optimum conditions 50°C and pH 8.5 which obtained from previous study performed by Demirhan et al. (2011). The amount of enzyme added to these solutions was 3 ml/L.

D. Conversion of hydrolysis

The hydrolysis of the reaction was monitored by pH stat method.

E. Protein concentration

Soluble protein concentration was determined by Lowry method using bovine serum albumin as standard. Soluble background protein concentration of sesame cake protein values were given as percentage of the initial protein concentration.

F. Protease activity

For measuring the residual enzyme activity azocasein was used as a substrate.

G. Amino Acid Analysis

The amino acid composition was determined with an amino acid analyser Shimadzu UFLC LC-20 AT.

III. RESULTS AND DISCUSSIONS

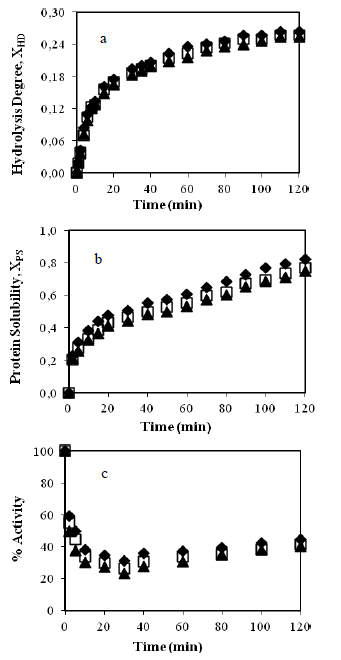

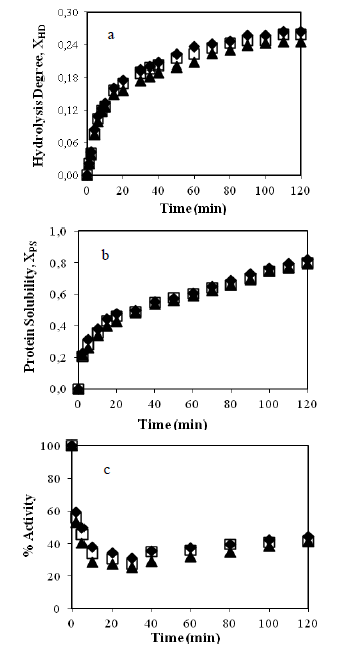

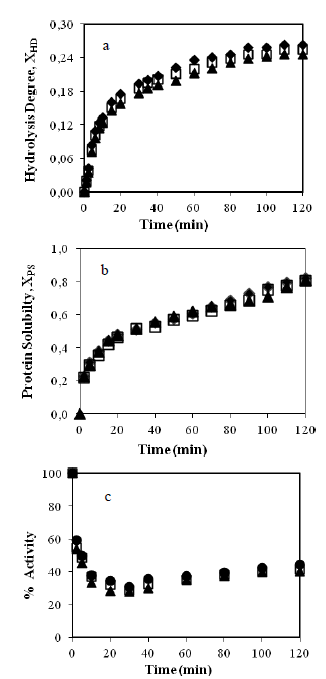

The effect of pretreatments on hydrolysis and solubility of sesame cake protein and stability of Alcalase were investigated, and the results were given in Fig. 1-3. As can be seen from these figures, no significant changes were observed on the hydrolysis degrees of sesame cake protein after heat, microwave and sonic treatment.

Figure 1: Effect of heat pretreatment a) Hydrolysis Degree; b) Protein Solubility; c) Activity (%) (T= 50°C, pH= 8.5, S= 15 g protein/L; E= 0.3% (v/v), (♦ control (without pretreatment), □ pretreatment at 90°C, ▲ pretreatment at 100°C)

Figure 2: Effect of microwave pretreatment a) Hydrolysis Degree; b) Protein Solubility; c) Activity (%) (T= 50°C, pH= 8.5, S= 15 g protein/L; E= 0.3% (v/v), (♦ control (without pretreatment), □ pretreatment at 540 W, ▲ pretreatment at 720 W)

Figure 3: Effect of sonic pretreatment a) Hydrolysis Degree; b) Protein Solubility; c) Activity (%) (T= 50°C, pH= 8.5, S= 15 g protein/L; E= 0.3% (v/v), (♦ control (without pretreatment), □ pretreatment at 80 W, ▲ pretreatment at 120 W)

The solubilization of sesame cake protein was slightly decreased with the pretreatments. The decreases observed in the solubilization could be attributed to the increase in the amount of background soluble protein after the pretreatments.

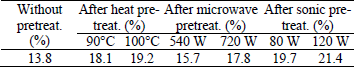

The amount of background soluble protein was increased after all pretreatments as represented in Table 1. On the other hand, it was observed that the stability of enzyme (%) was decreased after the pretreatments compared with the control experiment. These decreases could be explained by the denaturation at secondary structure and tertiary structure of protein.

Table 1: Soluble background protein concentration of sesame cake protein

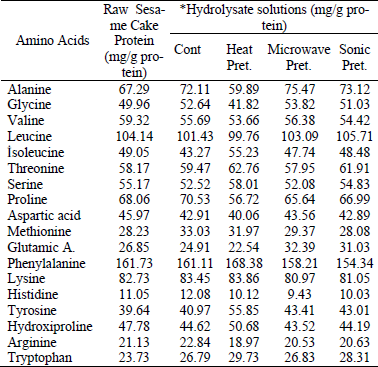

The amino acid composition of sesame cake protein was shown in Table 2. No significant differences were observed in the amino acid composition between the raw sesame cake protein and the pretreatment experiments. In this way, the nutritional value of sesame cake protein was maintained after the pretreatments.

Table 2: Effect of pretreatments on the amino acid composition of sesame cake protein hydrolysates

*Heat pretreatment at 100°C; Microwave pretreatment at 720 W; sonic pretreatment at 120 W acoustic power

IV. CONCLUSIONS

The effects of pretreatments (heat, microwave and sonic) on hydrolysis of sesame cake protein were investigated. It was observed that hydrolysis degree didn't change while solubilization and enzyme stability decreased after pretreatments. The amount of background soluble protein increased. On the other hand, the amino acid compositions of sesame cake protein were almost the same with the raw protein after pretreatments.

ACKNOWLEDGEMENTS

This research has been supported by Yıldız Technical University Scientific Projects Coordination Department (Project number: 29-07-01-01). Authors gratefully acknowledge to Novoyzmes and Necdet Bükey A.Ş for supporting the enzyme and sesame cake, respectively; and Elçin Demirhan gratefully acknowledges TUBITAK (Scientific and Technological Research Council of Turkey) for the scholarship.

REFERENCES

1. Chabanon, G., I. Chevalot, X. Framboisier, S. Chenu and I. Marc, "Hydrolysis of rapeseed protein isolates: Kinetics, characterization and functional properties of hydrolysates," Process. Biochem., 42, 1419-1428 (2007).

2. Cui, C., X. Zhou, M. Zhao and B. Yang, "Effect of thermal treatment on the enzymatic hydrolysis of chicken proteins," Innov. Food Sci. Emerg., 10, 37-41 (2009).

3. Demirhan, E., D.K. Apar and B. Ozbek, "Sesame cake protein hydrolysis by alcalase: Fffects of process parameters on hydrolysis, solubilisation and enzyme inactivation," Korean J. Chem. Eng., 28, 195-202 (2011).

4. Kim, J.M., J.H. Whang, K.M. Kim, J.H. Koh and H.J. Suh, "Preparation of corn gluten hydrolysate with angiotensin I converting enzyme inhibitory activity and its solubility and moisture sorption," Process. Biochem., 39, 989-994 (2004).

5. Nordqvist, P., M. Lawther, E. Malmström and F. Khabbaz, "Adhesive properties of wheat gluten after enzymatic hydrolysis or heat treatment - A comparative study," Ind. Crop. Prod., 38, 139- 145 (2012).

6. Ye, X. and L. Li, "Microwave-Assisted Protein Solubilization for Mass Spectrometry-Based Shotgun Proteome Analysis," Anal. Chem., 84, 6181−6191 (2012).

7. Zhong, H., S.L. Marcus and L. Li, "Microwave-Assisted Acid Hydrolysis of Proteins Combined with Liquid Chromatography MALDI MS/MS for Protein Identification," J. Am. Soc. Mass Spectrom., 16, 471-481 (2005).

Received: December 24, 2013

Accepted: September 17, 2014

Recommended by Subject Editor: María Luján Ferreira